Edge Glued Panel (EGP) is a panel shaped product. Laminated shields are made from relatively narrow calibrated timber materials, which are joined together sideways, thereby forming a panel shaped end product.

Laminated timber beams table height width s-standard size e-customized size max size, timber type: spruce

The dimensions for edge glued panels remain relatively constant as the stresses that engulf one part of the plate are compressed and alleviated in the other part of the plate

The decorative effect of edge glued panels can be enhanced by using lamellas made from different types of timber. Edge glued panel is most widely used by furniture manufacturers and the construction business when making built-in bespoke furniture. Some edge glued panels also find use as interior components of block boards.

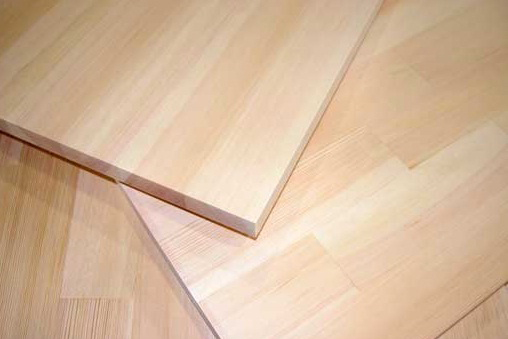

Edge glued panels are available in both single-piece lamella as well as finger jointed forms. Use of single-piece lamellas mean that lamellas which are glued together sideways comprise a single block running through the length of the piece. Single-piece lamellas lend themselves to manufacturing of pieces with lengths up to 2100 mm. Longer panels are all made by utilizing the finger jointed method. A panel glued together from single-piece lamellas looks as follows:

Finger jointed edge glued panels are manufactured by gluing together pieces of timber that have been notched along a comb-toothed pattern. It is widely used when making doorposts and window structures. Deformations of finger jointed materials are minimized in comparison to ordinary sawn timber – especially in conditions where there exist wide variations in interior and ambient temperatures.

Finger jointed materials are more affordable in comparison to products made from single-piece lamellas, as the finger jointed method enables the use of lower quality timber. In the manufacture of timber, some lower-quality surplus timber is always left over, which can then be used by finger joining together the surplus parts to make whole pieces. Lower quality parts such as branches, resin pockets, cracks, etc. are cut away and finger jointed together to make a good quality end product. The comb-toothed pattern is visible only from the profile, with a narrow stripe running across the top part of the plate. Hence the visual appearance of the panel is not compromised.

Displayed below: magnified view of a finger joint on a lamella

Edge glued panels are made to look like pieces of parquet (short stripes running along the horizontal line are the interconnecting joints of finger jointed lamellas)

Who might take an interest in edge glued panels?

– Furniture manufacturers

– Builders

– Cabinetmakers

Where are edge glued panels used?

– Wall constructions

– For making built-in bespoke furniture and regular furniture

– Flat work surfaces

What type of timber is used for making edge glued panels?

– Spruce (conifer) – on order

– Pine (conifer)*

– Birch (deciduous)*

– Oak (deciduous)*

– Beech (deciduous)*

– Cherry (deciduous) – on order

– Walnut (deciduous) – on order

– Maple (deciduous) – on order

* denotes types of timber readily available in-stock

What are the advantages of using edge glued panels?

– both stronger and more durable than ordinary timber

– not prone to cracking or drying

– will not alter shape or bend when drying

– can be cut to suitable shapes – triangles, ovals, bends, etc.

Standard dimensions for edge glued panels made from pine (given in millimetres)

| Thickness | Width | Length |

| 18 | 200 | 800; 1200; 1500; 2000; 2500 |

| 18 | 300 | 800; 1000; 1200; 2000; 2500; 3000 |

| 18 | 400 | 800; 1200; 1600; 2000 |

| 18 | 450 | 1500 |

| 18 | 600 | 800; 1200; 2000; 2500; 3000 |

| 28 | 300 | 1200; 2500; 3000 |

| 28 | 400 | 2500; 3000 |

| 28 | 800 | 2500 |

| 38 | 300 | 1000; 1600; 2500; 3000; 4000 |

| 38 | 400 | 1600 |

| 38 | 600 | 1000; 1600; 2500; 3000 |

| 38 | 800 | 2500 |

| 40 | 280 | 4500 |

Standard dimensions for edge glued panels made from birch (given in millimetres)

| Thickness | Width | Length |

| 20 | 200 | 800 |

| 20 | 200 | 1600 |

| 20 | 200 | 2000 |

| 20 | 300 | 800 |

| 20 | 300 | 1600 |

| 20 | 300 | 2000 |

| 20 | 400 | 800 |

| 20 | 400 | 1600 |

| 20 | 400 | 2000 |

| 27 | 600 | 3000 (denotes flat working surface with rounded corners) |

Standard dimensions for edge glued panels made from oak (given in millimetres)

| Thickness | Width | Length |

| 20 | 510 | 810; 910; 1010; 1210; 1410; 1610; 1810 |

| 20 | 620 | 1000; 1100; 1200; 1300; 1500; 1600; 1700; 1800; 2000; 2100; 3500; 4200; 4500 |

| 30 | 620 | 900; 1000; 1100; 1700; 3100; 3500; 3800; 4200; 4500 |

| 40 | 620 | 800; 900; 1000; 1100; 1200; 1300; 1500; 1700; 1800; 3500; 3800; 4200; 4500 |

| 40 | 1000 | 1900; 2000; 2100; 2200; 2500; 3000 |

| 40 | 1200 | 2000; 2100; 2200; 2300; 2500; 2600 |

| 50 | 620 | 1100; 1200 |

Standard dimensions for edge glued panels made from beech (given in millimetres)

| Thickness | Width | Length |

| 20 | 620 | 1250; 3500; 4500 |

| 30 | 620 | 900; 1600; 2000; 2400; 3500; 4500 |

| 40 | 300 | 1100; 1200 |

| 40 | 620 | 900; 1000; 1100; 1250; 1400; 1550; 1900; 4200; 4500 |

| 40 | 1200 | 2100; 2150 |